is a printing technique whereby a mesh is used to transfer ink onto the fabric, with certain parts of the mesh blocked by a stencil to create a design.

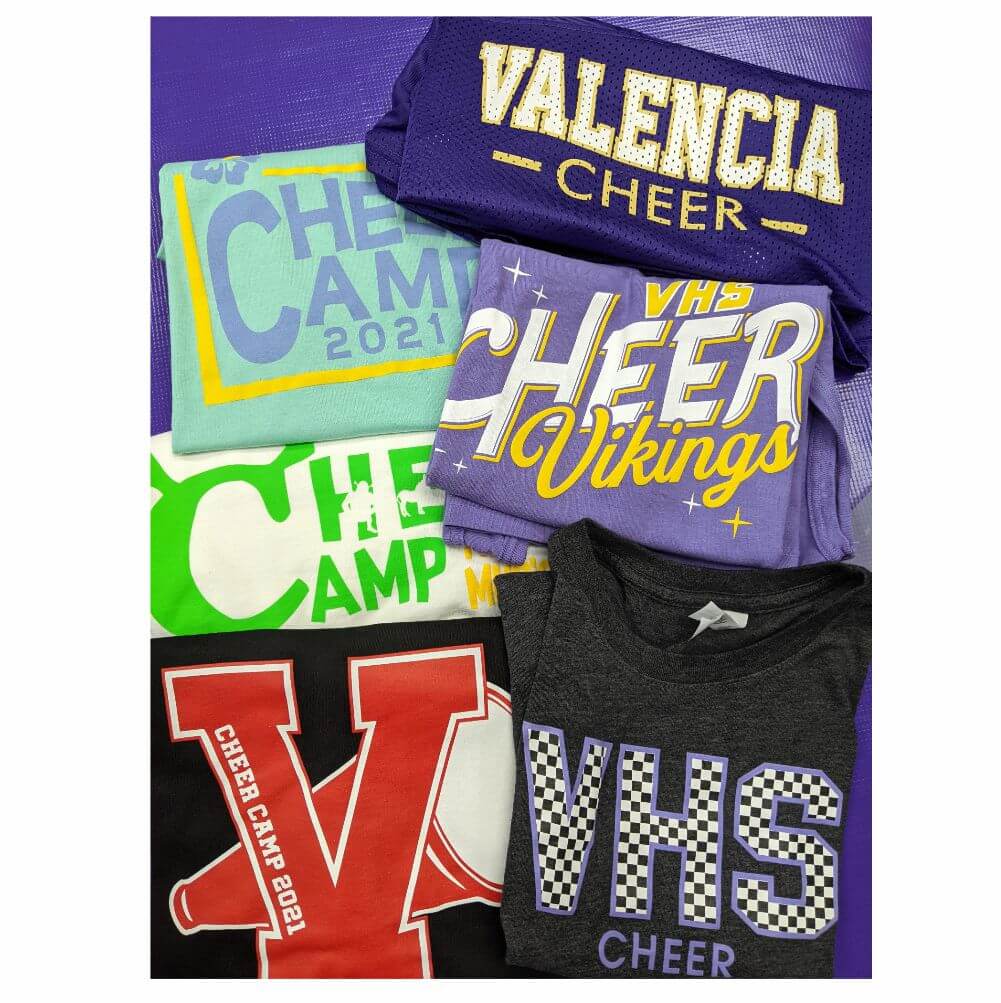

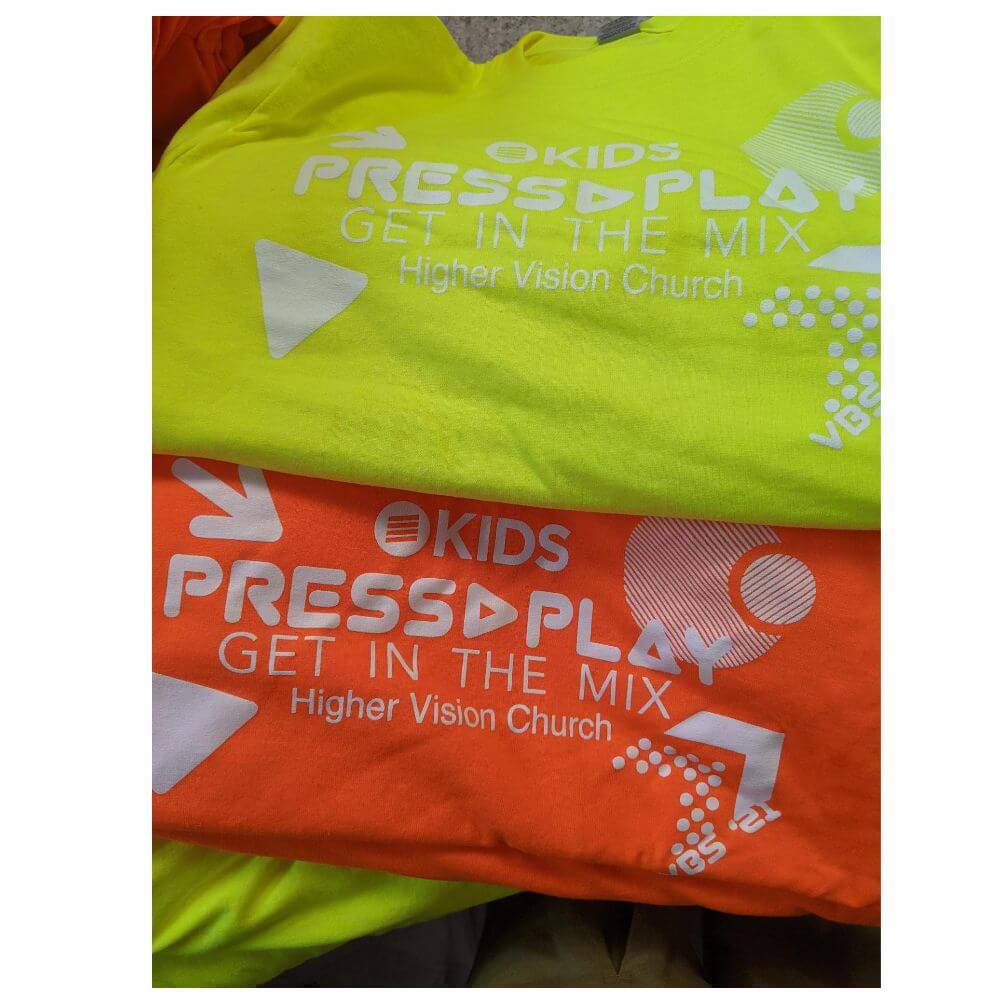

We do with many printing techniques to get the best result for your order. For example, water base inks, Metallic Inks, Foils, Full color process, Discharge technique or Half-Tone technique.

The Screen Printing Process: Bringing Your Custom Designs to Life with Quality and Precision

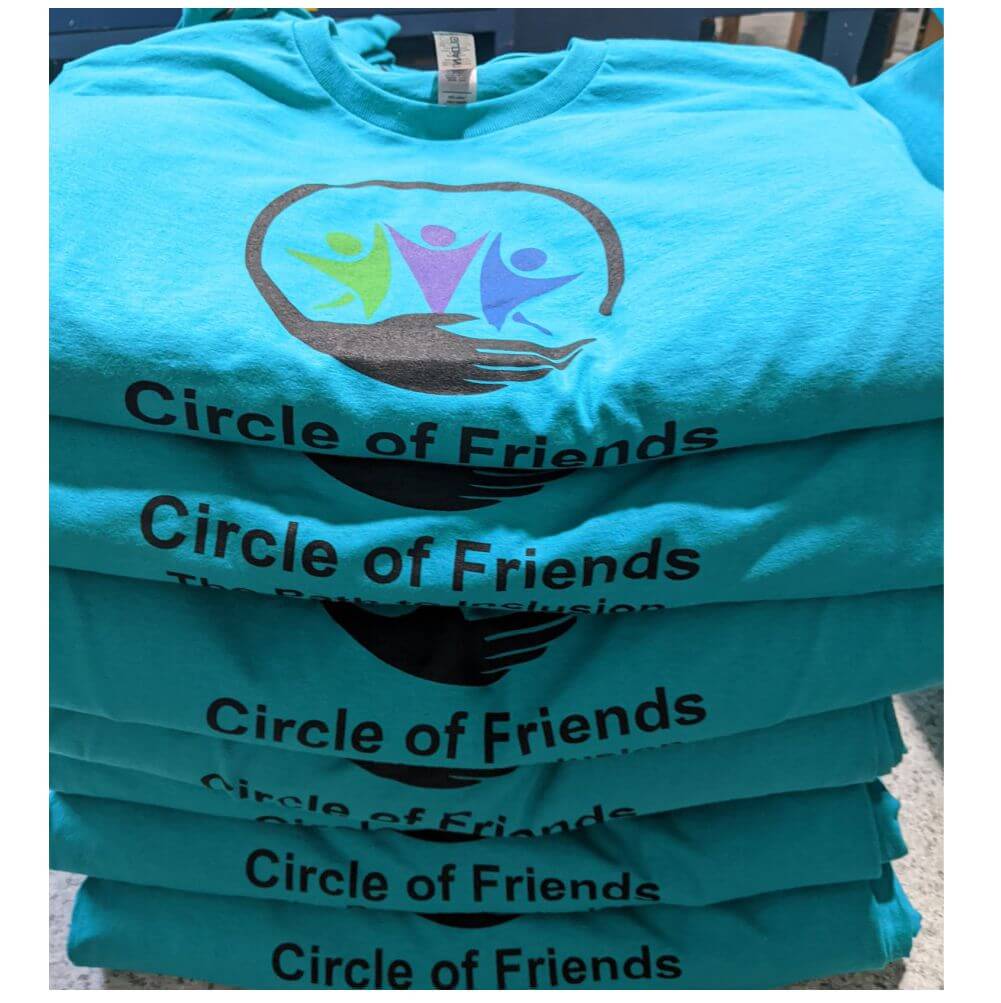

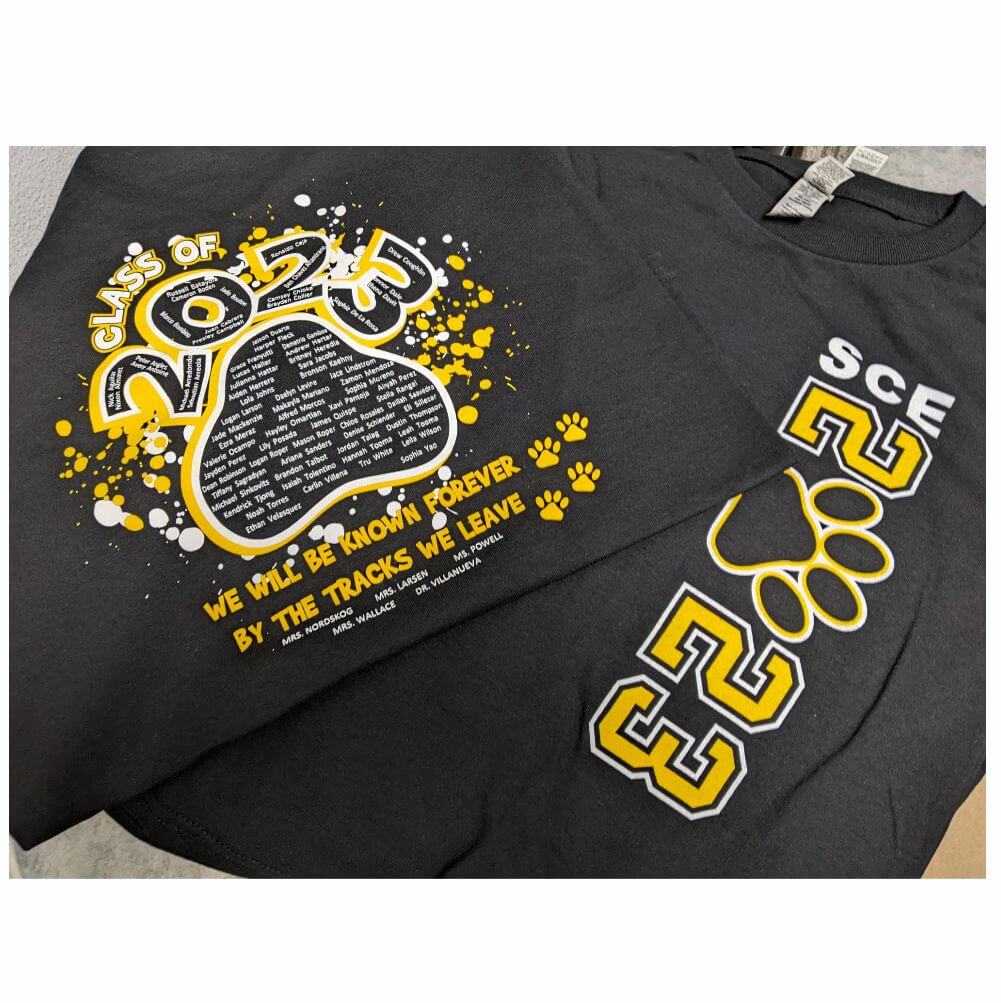

As a business owner or creator, you know the importance of making a lasting impression—whether it’s through custom shirts for your team, branded promotional items, or unique apparel for your customers. Screen printing is one of the most popular and effective methods for transferring custom designs onto fabric. It’s a versatile and durable technique that works on a wide variety of materials, making it the perfect choice for custom t-shirts, hats, jackets, and more. But how does screen printing work, and what makes it such a great option for creating high-quality, long-lasting custom apparel?

In this post, we’ll walk you through the entire screen printing process—from start to finish—so you can better understand how this technique can elevate your business’s branding and promotional efforts.

Setting up the screen for screen printing begins with preparing the mesh screen, which is coated with a light-sensitive emulsion. This emulsion is then exposed to a high-powered light source, with the design being transferred onto the screen using a film positive or a digital exposure unit. The areas where light hits the emulsion harden, while the unexposed areas remain soft, allowing the ink to pass through those parts. After exposing the screen, it’s rinsed with water to wash away the unexposed emulsion, leaving a stencil of the design on the mesh. The screen is then dried and carefully inspected for any flaws before being mounted onto the press.

The process of pressing ink through the mesh screen begins once the screen is aligned with the fabric on the printing press. Using a squeegee, the screen printer applies pressure to the ink, forcing it through the open areas of the mesh that make up the design stencil. The mesh screen itself is made of tightly woven threads, creating tiny openings that allow the ink to pass through only in the areas corresponding to the design. The ink flows through the mesh and onto the fabric, leaving a sharp, detailed image. Multiple passes may be required for multi-color designs, as each color needs its own screen, ensuring that the colors are applied in layers. The pressure, speed, and angle at which the squeegee is moved are carefully controlled to ensure consistent ink coverage and prevent smudging or uneven application.

Once the ink has been applied to the garment through the screen printing process, the next critical step is curing. Curing refers to the process of using heat to fully bond the ink to the fabric, ensuring durability and preventing fading or cracking. This is typically done using a conveyor dryer or a heat press that applies a consistent, high temperature to the garment. The specific temperature and duration depend on the type of ink used—plastisol ink, for instance, requires temperatures around 400°F to properly cure. During curing, the ink undergoes a chemical reaction where it solidifies and adheres tightly to the fabric fibers, creating a long-lasting, vibrant design. Failure to properly cure the ink can result in a design that fades or cracks over time, compromising the quality of the final product.

After the screen printing process is complete, it’s time for quality control. Each garment is carefully inspected for any imperfections such as ink smudges, or alignment issues. Any issues found are corrected, and the final product is made ready for delivery. Garments are folded, packaged, and prepared for shipment or pickup, ensuring they arrive in pristine condition, ready to showcase your custom design.

Are you ready to bring your logo to life? Reach out by leaving an inquiry at our contact us page or give us a call at (661) 753-3720